Data dhasar

Tipe dhasar:

1. Gaya konduktor tunggal terisolasi

2. Gaya konduktor kembar

3. Un-terisolasi kabel ujung lengan

Karakteristik

Total bagean salib: 0,25 ~ 150mm²

Kode warna lan dimensi tabung kanggo DIN 46228, bagean 4 (0.5 ~ 50mm²)

Halida free, Flame retardant bisa nampa

Tahan panas nganti 105 ℃ (PP) 120 ℃ (PA)

Bahan:

99% Tembaga murni

Sintetik: Polipropilena (PP), Poliamida (PA)

lumahing

Timah-dilapisi kanggo nglindhungi marang karat

Info pesenan

Saiki uga kasedhiya ing kothak plastik praktis kanggo syarat sing luwih cilik.Ing kahanan normal, kita ora duwe syarat MOQ kanggo kemasan tas.

Data Teknis

Bahan Konduktif (kajaba Range Sambungan Cepet)

| Tembaga | 99,9% resik |

| Kekuwatan Tensile | 200MPa |

| Rating ulet | 35% |

| State Metal pungkasan | Bagéyan saka produk anil |

| Kandungan Oksigen | 50 ppm maks |

|

|

|

| Kuningan | 30% Seng 70% Tembaga |

| Kekuwatan Tensile | 580 Mpa |

| Rating ulet | 6% min |

| State Metal pungkasan | Bagéyan saka produk anil |

|

|

|

| Bahan | timah |

| Kandungan Tin | 99,90% |

| Logam liyane | Timbal + Antimon |

| Ketebalan Plating | 1,5 mikron |

|

|

|

| Konduktivitas Umum | 98,5% IACS |

| Total Resistivitas | 1,738 mikro-ohm cm |

|

|

|

| Bahan | PVC kanggo kabeh kajaba nilon 6 utawa nilon 66 - kanggo IQC |

| Tegangan rusak | 1,5 k V (min) |

| Resistance insulasi | Ndhuwur 100 meg ohm |

| Tegangan kerja | Nganti 300V AC/DC |

|

|

|

| Pre-Insulate | -40 ℃ nganti + 150 ℃ |

| Kuningan | 145 ℃ |

| Dilapisi timah | 160 ℃ |

SPESIFIKASI

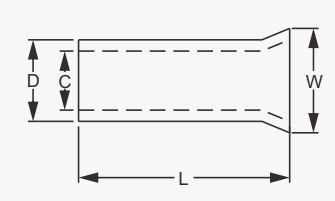

| bagean silang (mm²) | Item No. | Ukuran (mm) | AWG |

| bagean silang (mm²) | Item No. | Ukuran (mm) | AWG | ||||||

| L | W | D | C |

| L | W | D | C | ||||||

| 0.25 | EN0206 | 6 | 1.5 | 1.1 | 0.8 | #26 |

| 10 | EN10-18 | 18 | 5.8 | 4.9 | 4.5 | #8 |

| EN0208 | 8 |

| EN10-20 | 20 | ||||||||||

| 0.34 | EN0306 | 6 | #24 |

| EN10-25 | 25 | ||||||||

| EN0308 | 8 |

| 16 | EN16-12 | 12 | 7.2 | 6.2 | 5.8 | #6 | |||||

| 0.5 | EN0506 | 6 | 1.7 | 1.3 | `1.0 | #22 |

| EN16-16 | 16 | |||||

| EN0508 | 8 |

| EN16-18 | 18 | ||||||||||

| EN0510 | 10 |

| EN16-20 | 20 | ||||||||||

| EN0512 | 12 |

| EN16-22 | 22 | ||||||||||

| 0.75 | EN7506 | 6 | 1.9 | 1.5 | 1.2 | #20 |

| EN16-25 | 25 | |||||

| EN7508 | 8 |

| 25 | EN25-12 | 12 | 9.1 | 7.9 | 7.5 | #4 | |||||

| EN7510 | 10 |

| EN25-16 | 16 | ||||||||||

| EN7512 | 12 |

| EN25-18 | 18 | ||||||||||

| 1.0 | EN1006 | 6 | 2.2 | 1.7 | 1.4 | #18 |

| EN25-22 | 22 | |||||

| EN1008 | 8 |

| EN25-25 | 25 | ||||||||||

| EN1010 | 10 |

| 35 | EN35-16 | 16 | 10.2 | 8.7 | 8.3 | #2 | |||||

| EN1012 | 12 |

| EN35-20 | 20 | ||||||||||

| EN1018 | 18 |

| EN35-25 | 25 | ||||||||||

| 1.5 | EN1508 | 8 | 2.5 | 2.0 | 1.7 | #16 |

| 50 | EN50-12 | 12 | 12.7 | 10.9 | 10.3 | #1 |

| EN1510 | 10 |

| EN50-18 | 18 | ||||||||||

| EN1512 | 12 |

| EN50-22 | 22 | ||||||||||

| EN1518 | 18 |

| EN50-25 | 25 | ||||||||||

| 2.5 | EN2506 | 6 | 3.3 | 2.6 | 2.3 | #14 |

| 70 | EN70-22 | 22 | 15.8 | 14.3 | 13.5 | 2/0 |

| EN2508 | 8 |

| EN70-25 | 25 | ||||||||||

| EN2510 | 10 |

| EN70-32 | 32 | ||||||||||

| EN2512 | 12 |

| 95 | EN95-25 | 25 | 17.3 | 15.6 | 14.8 | 3/0 | |||||

| EN2518 | 18 |

| EN95-30 | 30 | ||||||||||

| 4 | EN4009 | 9 | 3.9 | 3.2 | 2.8 | #12 |

| EN95-34 | 34 | |||||

| EN4012 | 12 |

| 120 | EN120-30 | 30 | 20.2 | 17.7 | 16.7 | 4/0 | |||||

| EN4018 | 18 |

| EN120-34 | 34 | ||||||||||

| 6 | EN6010 | 10 | 4.7 | 3.9 | 3.5 | #10 |

| EN120-38 | 38 | |||||

| EN6012 | 12 |

| 150 | EN150-32 | 32 | 23 | 20.6 | 19.6 | 250/300 | |||||

| EN6018 | 18 |

| EN150-40 | 40 | ||||||||||

| 10 | EN10-12 | 12 | 5.8 | 4.9 | 4.5 | #8 |

| 185 | EN185-32 | 32 | 23.9 | 21.4 | 20.2 | 300/350 |

| EN10-16 | 16 |

| EN185-40 | 40 | ||||||||||